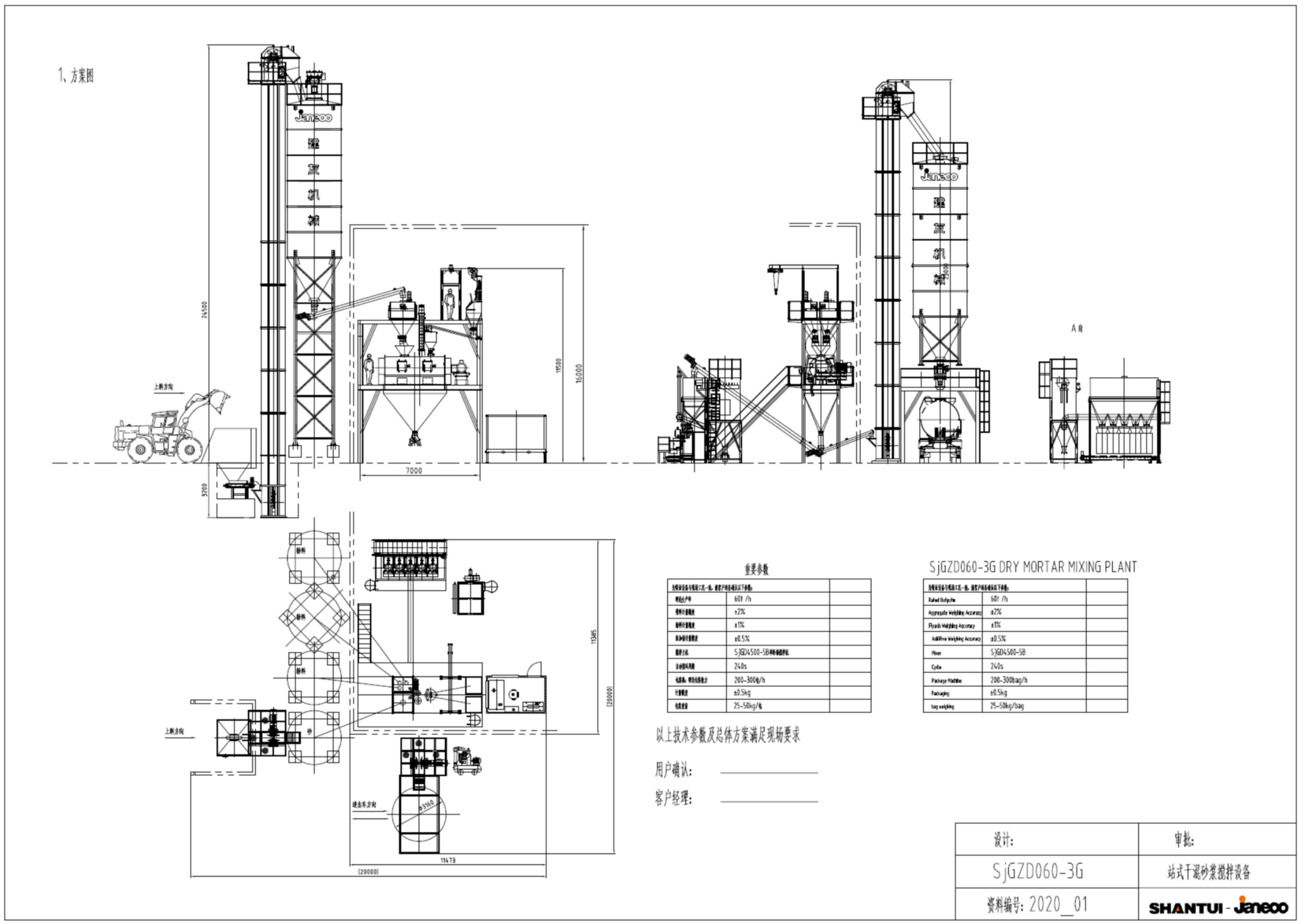

SjGZD060-3G Station Typ Dréchen Motar batching Planz

Main Spezifikatioune

1.main Spezifikatioune

Theoretesch Produktivitéit 60t/h

Mixer SjGD4500-5B

Aggregéiert Miessgenauegkeet 2

Zementmiessgenauegkeet 1%

Additiv Messgenauegkeet 0,5%

Sand Silo Volume 72m3

Zement Silo Volume 72m3

Additiv Silovolumen 0,5m3

Verpakung Kapazitéit 200-300bags / h / Set

Gesamtleistung 140 kW (ausser Silo- a Schraubetransporter)

1.Sand Silo

| Volumen | 72m vun3 |

| Duerchmiesser | 3, 2m |

2.Zement Silo

| Volumen | 72m vun3 |

| Duerchmiesser | 3, 2m |

3.Additiv Silo

| Volumen | 0,5m 3 |

4.Sand batching Schrauwen conveyor

| Schrauwen Duerchmiesser | 323 mm ép |

| Kapazitéit | 35m vun3/h |

5.Sand batching Schrauwen conveyor

| Schrauwen Duerchmiesser | 273 mm |

| Kapazitéit | 50m3/h |

6.aggregéiert Mooss Hopper

| Typ | elektronesch Skala |

| Max Wäert | 3000 kg |

| Genauegkeet | ± 2% |

7.Zement Mooss Hopper

| Typ | elektronesch Skala |

| Max Wäert | 2500 kg |

| Genauegkeet | ± 1% |

8.Additive Mooss Hopper

| Typ | elektronesch Skala |

| Max Wäert | 150 kg |

| Genauegkeet | ± 0,5% |

9.Mixer

| Mixer | SjGD4500-5B |

| Motor Muecht | 90kw eng |

| Blade Muecht | 4 x 5,5 kW |

10.Packmaschinn

| Verpakung Kapazitéit | 200-300 Poschen / h / Set |

| All Sak Gewiicht | 25-50 kg |

| Genauegkeet | ± 0,5 kg |

11.pneumatesch System

| Loft Kompressor Muecht | 30 kW an |

| Drock | 0,75 MPa |

12. Stëbs Ewechhuele System

| Filter | 60m vun2 |

| Muecht | 7,5 kW |

20.elektresch System

De System gëtt ugedriwwen duerch AC 380V an 50Hz Dräi-Phase véier (fënnef) Drot System.

21.Computer Kontroll

Manuell an automatesch

22.zyklus Zäit

| Auto | 240s |

Beschreiwung

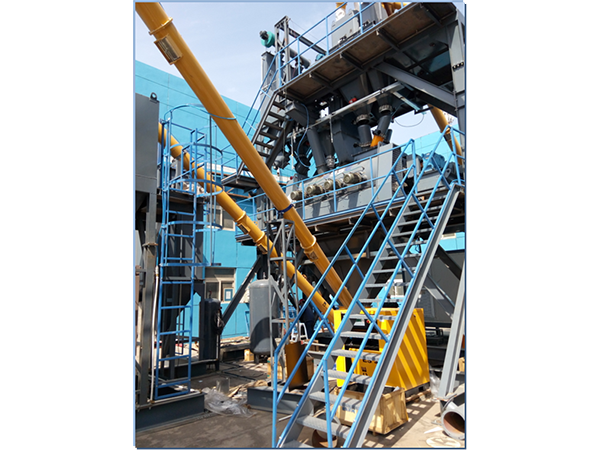

SjGZD060-3G Station Typ dréchen Mörser Vermëschung Ausrüstung ass eng Zort Ausrüstung entworf an entwéckelt vun eiser Firma no den ähnlechen Produkter am Ausland a kombinéiert mat der aktueller Situatioun an China.

D'Haaptrei Ausrüstung adoptéiert Statioun Struktur, dorënner 1 Sand bin (72m3 / Stéck), 3 Pudder bin (72m3 / Stéck), an 2 additive bin (0.5m3 / Stéck). op de Pudder Silo vun engem Bulk Tank Camion, an déi zwee Zousätz sinn op d'Additiv Silo Layer vun engem elektresche Levée Apparat opgehuewe a manuell an den Zousaz Silo gesat. , Miessgenauegkeet ass héich, kleng Feeler. D'Kontrollsystem adoptéiert manuell an automatesch Kontroll. De System huet perfekt Selbstverschluss- an Inter-Spärfunktiounen fir eng korrekt an zouverléisseg Operatioun vum System ze garantéieren, an huet gemeinsame Feelererkennung an Alarmfunktiounen.

Configuratioun

| 一, Haaptgebai | ||||

| Nee. | Beschreiwung | Artikel | Quty | Bemierkung |

| 1 | Gewiichtskala | 1 |

| |

| Gewiichtskala Max.3000kg | 1 | |||

| Drock Lueden Zell | 3 | |||

| Lueden Zell Verbindung Deeler | 3 | |||

| (DN300) pneumatesch Schmetterlingsventil (DN300) | 2 | |||

| MVE60/3 Vibrator MVE60/3 | 1 | |||

| Zement Gewiicht Skala Max.2500kg | 1 | |||

| Drock Lueden Zell | 3 | |||

| Lueden Zell Verbindung Deeler | 3 | |||

| pneumatesch Schmetterlingsventil (DN250) | 2 | |||

| Vibrator MVE60/3 | 1 | |||

| 2 | additive Stockage Silo | 1 |

| |

| Additivbehälter (Volumn: 0.5m3) | 2 | |||

| Resistenz Twist-Aktioun Indikator | 2 | |||

| manuelle Schmetterlingsventil (DN250) | 2 | |||

| transverter | 1 | |||

| Vibrator MVE60/3 | 2 | |||

| 3 | additiv Gewiichtskala | 1 |

| |

| Max.Gewiichtskala 150 kg | 1 | |||

| Lueden Zell | 3 | |||

| pneumatesch Schmetterlingsventil (DN200) | 1 | |||

| pneumatesch Schmetterlingsventil Ø250 | 1 | |||

| MVE60/3 Vibrator MVE60/3 | 1 | |||

| 4 | additiv hoisting Apparater | 1 |

| |

| Kader | 1 | |||

| 1000Kg Elektresch Hoist 1000KG | 1 | |||

| 5 | 手工投料装置Manuelle Fudderapparat | 1 |

| |

| manuell fidderen | 1 | |||

| pneumatesch Schmetterlingsventil (DN200) | 1 | |||

| 6 | Vermëschung System |

|

| |

| Ënnerstëtzung Basis (Q235 Stol Struktur) | 1 | |||

| Tank Kierper (16Mn Stol Struktur) | 1 | |||

| Zougang Gate (16Mn Stol Struktur) | 2 | |||

| ass Charging Gate (16Mn Stol Struktur) | 1 | |||

| 90KW Vermëschung Apparater | 1 | |||

| Vermëschung Schacht an Schacht Enn | 1 | |||

| Ausluedegeräter | 1 | |||

| Sampling Apparat | 1 | |||

| Probe Rouer Kierper (Struktur Komponente) | 1 | |||

| Prouf Zylinder | 1 | |||

| manuelle Richtungsventil | 1 | |||

| Hëllefsmixgeräter | 4 | |||

| Fly Cutter Apparat | 4 | |||

| 7 | fäerdeg Hopper | 1 |

| |

| Hopper Kierper (16Mn) | 1 | |||

| Resistenz Twist-Aktioun Indikator | 1 | |||

| Vibrator MVE60/3 | 1 | |||

| manuelle Schmetterlingsventil (DN250) | 2 | |||

| 8 | Produkter Verpakung | 1 |

| |

| fäerdeg Hoop | 1 | |||

| Kader | 1 | |||

| Resistenz Twist-Aktioun Indikator | 2 | |||

| Vibrator MVE60/3 | 1 | |||

| Ventil Pocket Verpackungsmaschinn | 1 | |||

| Riem (L=4500m,B=650mm,2.2kw) | 1 | |||

| 9 | Stëbs-Ewechhuele Apparat | 1 |

| |

| 7.5KWPulse Schlagfilter | 1 | |||

| Staubentfernung Piping | 1 | |||

| 10 |

| 1 |

| |

| 30KWair Kompressor 30KW | 1 | |||

| AFF22C-10D Fotoen | 1 | |||

| 1m3 vun | 1 | |||

| Gas-Wee gemeinsame | 1 | |||

| 11 | Kontroll System | 1 |

| |

| Computer | 1 | |||

| elektresch Komponenten | 1 | |||

| LCD Monitor | 1 | |||

| 打印机 Drécker | 1 | |||

| UPS | 1 | |||

| Kontrollkonsole | 1 | |||

| Cabinet | 1 | |||

| Drot, Kabel a Bréck. | 1 | |||

| 12 | Kontrollraum | 1 |

| |

| Kontrollraum Kader | 1 | |||

| Kontrollraum dekoréieren | 1 | |||

| Beliichtung a schalt | 1 | |||

| Klimaanlag 1P | 1 | |||

| 13 | Stol Struktur | 1 |

| |

| Plattform | 1 | |||

| Leeder | 1 | |||

| Landung Been | 1 | |||

| Schrauwen conveyer | ||||

| 14 | φ323X5500mm 18,5KW Schraubetransporter | 1 |

| |

| 15 | φ323X3000mm 15KW Schraubetransporter | 1 |

| |

| 16 | φ219X5000mm 7,5KW Schraubetransporter | 1 |

| |

| 17 | φ219X7000mm 7,5KW Schraubetransporter | 1 |

| |

| 18 | φ219X9000mm 9,2KW Schraubetransporter | 1 |

| |

| 19 | Ø114x1500mm, Schraubetransporter | 2 |

| |

| 20 | Ø323-9000 Schraubetransporter | 1 |

| |

| 21 | SNC 100 silo | Duerchmiesser: 3.2m, V: 72m3 | 3 |

|

| Arch Break Apparat | 3 |

| ||

| Manuell Ventil (DN300) | 3 |

| ||

| Rotary Niveau Meter | 6 |

| ||

| Silo Top sécher Ventil | 3 |

| ||

| Silo Top Puls zréck Spullfilter | 3 |

| ||

| 22 | SNC 100 silo | Duerchmiesser: 3.2m, V: 72m3 | 1 |

|

| Manuell Ventil (DN300) | 1 |

| ||

| Rotary Hiewel Meter | 2 |

| ||

| Silo Top Puls zréck Spullfilter | 1 |

| ||

| 23 | SNC 100 silo | Duerchmiesser: 3.2m, V: 72m3 | 1 |

|

| Arch Break Apparat | 1 |

| ||

| Manuell Ventil (DN300) | 1 |

| ||

| Rotary Niveau Meter | 2 |

| ||

| Silo Top Puls zréck Spullfilter | 1 |

| ||

| Ënnerstëtzung Been, Silo Kierper an Accessoiren | 1 |

| ||

| 24 | Eemer Lift 60m3 / h | 2 |

| |

| Lift (24m, 11kw) | ||||

| Leeder an Ënnerhalt Plattform | ||||

| Füttern an Entlaascht | ||||

| 25 | pneumatesch Ventil | 1 |

| |

| ënnerstëtzen Basis | 1 | |||

| cilinder | 1 | |||

| elektromagnetesche Ventil | 1 | |||

| 26 | Bulk Mörser loader | Bulk Mörser loader | 1 |

|

| 27 | Hopper | 1 |

| |

| buchet | 1 | |||

| (B = 650 mm, 2,2 kW) Riem | 1 | |||